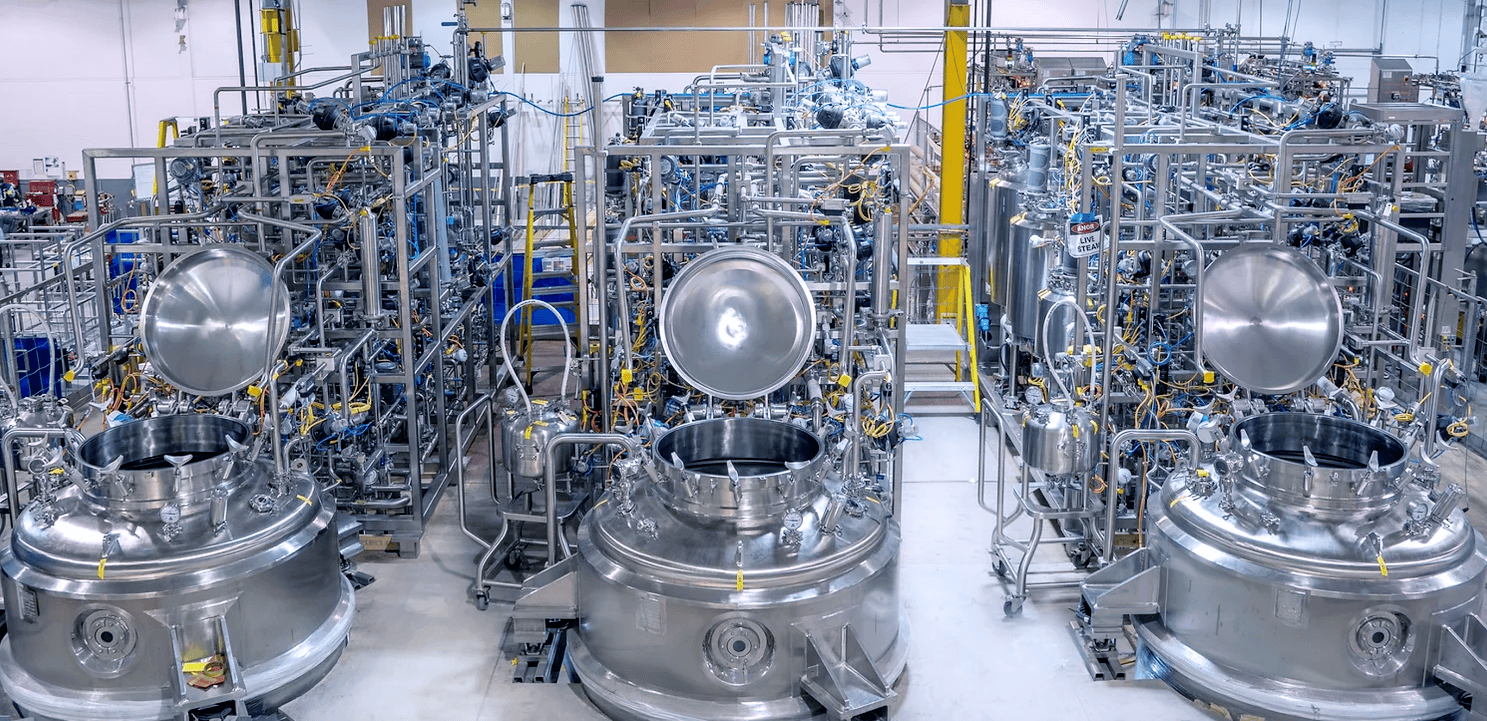

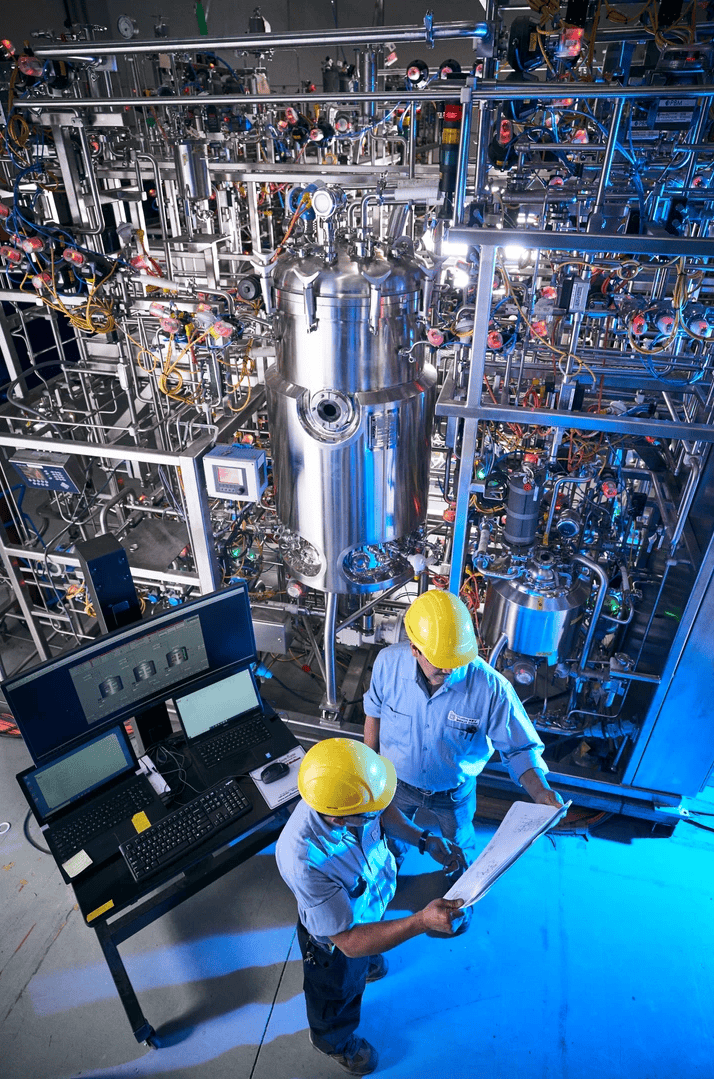

Manufacturing Center

A Time Lapse of a Large Scale Modular Integrated Process System

At TK modular, Custom is our Standard & Modular is our Product.

To provide modular process systems for the Biopharm Industry requires a unique set of abilities and specialized knowledge. Our unique skill sets can only be attained through extensive and prolonged years of process engineering, detailed design, & fabrication experience. These are distinctive capabilities that sets TK modular above the competition.

Our in-house, process know-how and fabrication expertise, allows us to provide The Best Way To Design & Build Modular Systems for our clients. For over 20 years our engineering and construct teams have provided many modular systems to our clients.

We have the expertise to develop the design and perform all the required disciplines in-house.

We have the in-house experience that allows for effective communication with clients throughout the design and build phases.

We have the skills and experience to procure the materials for the fabrication of the systems.

We deliver in a timely manner and have the experience in managing worldwide shipments.

We are responsible for the entire process and before we ship . . . . . . We Test Fully.

In the end, TK modular delivers.

Engineering & Design

Our in-house design team consists of the following:

- Mechanical and Structural Design

- Process Engineering – preliminary to detail

- Full BOM including tag lists and component specs

- 3D modeling of systems, including suite layouts

- Full electrical design, including I&E

- Experienced project management

- Full documentation to support validation

- 3D planning for setting of systems and equipment

Fabrication

The TK modular factory is configured to separate frame and support structure materials and fabrication from the high purity piping.

A separate warehouse is dedicated for clean material storage and allows for detailed QA inspection and tagging, as well as “kitting” of all components prior to arrival on our factory floor.

Kits are prepared using spool drawings, allowing our skilled fabricators to prepare piping spools prior to items such as pumps, tanks and instruments being received.

This approach to fabrication allows us to assemble systems quickly and optimize the timeline to manufacture.

In our factory, we perform the following:

- In-House inspection for material receiving

- Frame and platform fabrication

- Pipe spooling using orbital automatic welding

- Boroscope inspection and logging of process welds

- X-ray Inspection, when required

- Polishing and final finish to meet Industry standards

- Cleaning & passivation of systems and equipment

- Pressure testing to comply with TSSA & ASME

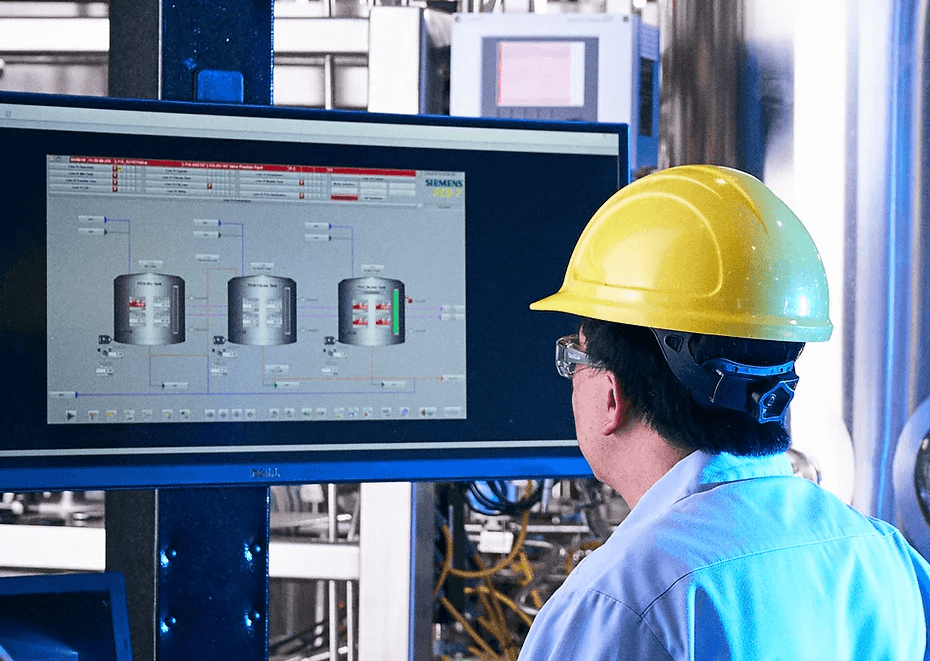

Testing

The testing of modular systems is a key requirement of our Quality Program.

Our factory is outfitted with the following services:

- Utility bays with raw & clean steam

- Filtered & dried compressed air

- Two tank CIP / Passivation system

- DI water distribution system with 15,000L storage vessel and a central utility distribution loop with point of use drops throughout the factory

- 400 AMP & 600 V with transformers for 208 & 460 Volt testing

- Drive-in Bay for loading and shipping large modular sections

Our client FAT rooms are within close proximity to the factory floor allowing for access to inspect their systems during FAT. We provide full capabilities for running automation and allow for the simulation of client operating conditions prior to shipment.

When our systems have completed testing and signed off by our clients, we prepare for shipment by properly crating the modules and ensuring the equipment is protected from weather conditions and adding a provision for loading and lifting conditions when at their site.

We have experience with ground, sea and air shipments, which allows TK modular to deliver modules throughout the world.