Factory Acceptance & Testing

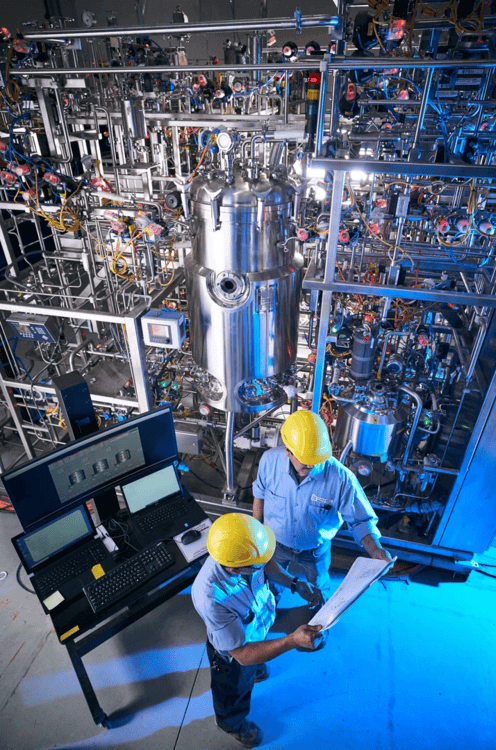

At TK modular, Factory Acceptance Testing (FAT) is a process that evaluates our equipment and systems during and after the assembly process by verifying that it is built and operating in accordance with client design specifications.

Our Factory Acceptance Testing ensures that the components and controls are working in accordance with the functionality of the equipment itself. As the name suggests, this testing is performed in our factory.

FAT is conducted to determine discrepancies and non-conformities, as well as developing a process for how they are to be corrected. Discrepancies observed during testing are documented in a problem report and corrected prior to shipment.

Clients will initiate a sign off to enable TK modular to ship the modules to their site.

Benefits of a Factory Acceptance Test at TK modular:

It provides a proof of functionality, quality, and integrity with our comprehensive checking process

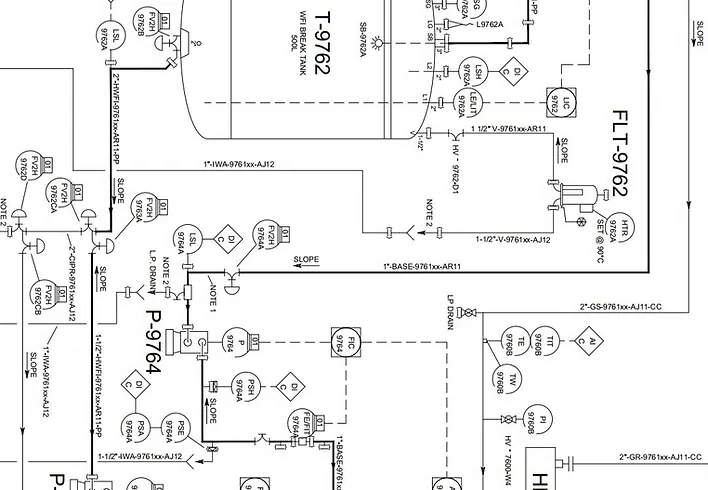

Verifies of all important documents, including component manuals, instructions, electrical plans, drawings, piping and instrumentation diagrams (P&IDs) as well as operational instructions.

Ensures that our client’s modular systems perform as expected under the design conditions.

During the FAT we check for the following:

The components used meet the specifications issued by our clients

All equipment is installed according to manufacturer’s and owners specifications

The control system inputs and outputs are connected according to the drawings

The calibration of the equipment is correct (where possible)

The software (when provided by TK modular) operates according to the system requirements and the outputs

and their actions operate according to the design.

At TK modular we provide the following upon acceptance of a FAT:

A full documentation and turn-over package, including a completed FAT Protocol

Maintenance and users’ manuals

Certificates of Compliance

As-built technical drawings (Electrical, Mechanical, Pneumatic, & Process)

Material certification and data sheets

Main equipment data sheets

Instruments calibration certificates

Welding processes qualifications

Weld logs and maps including full QA documentation of each welder

How do we conduct a Factory Acceptance Test?

There are several components that make up a FAT. Each modular system must first be assembled, prepared and connected to utilities for testing. All documentation such as drawings, ASME Certification and test procedures must be gathered. and agreed to. Finally, testing must be conducted in the factory following the agreed test procedures in order to prepare for the FAT.

Before the FAT begins, we issue our FAT procedure to the client for review and approval. The procedure includes testing of as much functionality as is practical in the factory and, when possible, show Pass/Fail criteria or desired results for each item tested. Once the procedure is approved, we test the equipment before the FAT begins. Sometimes our clients prefer to visit our factory prior to the actual FAT and this “Pre-Test” will confirm that the modular systems are established with the correct options, to ensure a smoother FAT testing process and thereby minimize any down-time during the FAT timeline.

A successful FAT includes Pressure Hold Tests, Riboflavin Testing, CIP and SIP Routing, Line Sloping, Dead Leg Inspection, Correct Component Installation, Proper Placement of Components, Correct Finish on Stainless Steel Materials, Proper Authority Inspection and Documentation Reviews.